SMC-K1000MVI 4 Axis High Grade Milling/Drilling CNC Controller

Feature:

1. 4 axis movement, 4 axis interpolation linkage movement.

2. 4 stepper/servo motor control.

3. Independent servo spindle.

4. Speed prospect processing, control the speed transition smooth.

5. Support straight line magazine, disc magazine, cylinder tool change and magazine features customize.

6. System self diagnose and parameters backup, recovery function.

7. Support USB, Ethernet, serial communication, U disk, SD card operation.

8. Support MPG running G code.

9. G code track preview, real-time tracking and syntax check function.

CNC System Function:

1. X, Y, Z, A four axis micron level interpolation accuracy controlling;

2. Can be configured with the stepper/servo drive, to achieve high performance to price ratio according to different users'

requirement.

3. USB/U dis/RS232COM etc many kinds of communication mode, to help users achieve different data transmission and

software upgrades easily.

4. Network interface, supporting for remote monitoring and DNC file transfer processing

5. Open platform, customizing special system according to customer demand.

6. Perfect self diagnosis function, internal and external status real-time display, alarm immediately when abnormal.

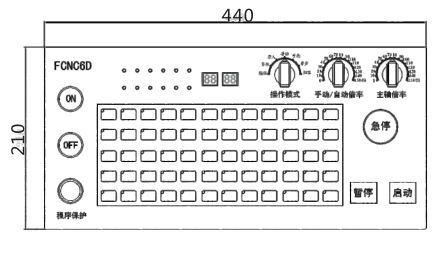

7. With external additional panel, hand box operation, convenient to operate.

8. Macro variable, macro definition programming,realizing a variety of logical relations. Support macro program with parameters ,

convenient to the user programming

9. High speed intelligent speed preconditioning motion processing,stable processing.

10. Using ARM processor and FPGA motion control technology,processing speed up to 60m/min

11. RS485 expansion bus, with IO peripheral extension.

12. Adopt international standard G code, with large storage space, support multi file and large file processing and storage.

13. Support the powerful B macro resolution function, to facilitate users to develop their own motion control program

14. DXF+G code template graphics analysis.

15. Forward and trajectory smoothing algorithms for up to 2000 segments, support NURBS spline interpolation.

16. Save automatically when power failure, password protection, screensaver.

CNC System Application:

1. Metal parts processing (car / boat, electrical hardware processing industry).

2. Glass products (mobile phones, televisions, computers, electrical switches and other glass panel processing).

3. Wooden furniture garden art (furniture, handicrafts, wooden temple sculpture landscaping).

4. Flexible processing line (milling, grinding, polishing and other processes producing line factory).

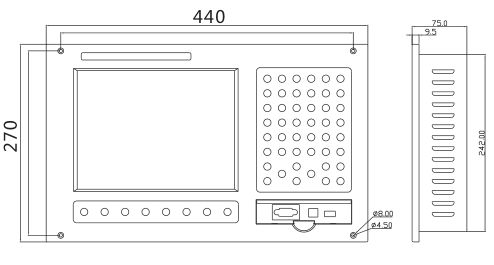

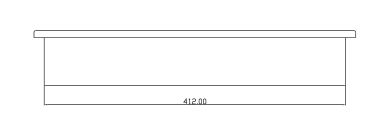

Size: