SMC-K1000MVII 6 Axis Milling/Drilling CNC Controller

Feature:

1. 6 axis movement, 6 axis interpolation linkage movement;

2. 6 stepper / servo motor control;

3. Independent servo spindle;

4. Speed prospect processing, control the speed transition smooth;

5. Support straight line magazine, disc magazine, cylinder tool change and magazine features customize;

6. System self diagnose and parameters backup, recovery function;

7. Support USB, Ethernet, serial communication, U disk, SD card operation;

8. Support MPG running G code;

9. G code track preview, real-time tracking and syntax check function.

CNC System Function:

1. Control axis number X, Y, Z, A, B, C six axis micron level interpolation accuracy;

2. Can be configured according to different user needs to configure the stepper, servo drive, to achieve high cost;

3. USB, U disk, RS232COM communications and other communication methods, easy to help users achieve different data

transmission requirements and software upgrades;

4. With network interface, support for remote monitoring and DNC file transfer processing;

5. Open platform, according to customer demand for customized special plane system;

6. Perfect self diagnosis function, internal and external status real-time display, abnormal immediately alarm;

7. Support external additional panel, hand box operation, convenient customer knife;

8. Macro variable, macro definition programming, the realization of a variety of logical relations. Support with parameters of the

macro program call, the user programming more convenient;

9. High speed intelligent speed pretreatment processing, processing stability;

10. With RS485 expansion bus, support IO peripheral expansion;

11. Using international standard G code, with large storage space, support multi file and large file processing and storage;

12. Support the powerful B macro analysis function, to facilitate users to develop their own motion control program;

13. As many as 2000 segments of the forward and trajectory smoothing algorithms, support for NURBS spline interpolation;

14. Power save function, password protected screen saver function etc.

CNC System Application:

1. Metal parts processing (car / boat, electrical hardware processing industry);

2. Glass products (mobile phones, televisions, computers, electrical switches and other glass panel processing);

3. Wooden furniture garden art (furniture, handicrafts, wooden temple sculpture landscaping);

4. Flexible processing line (milling, grinding, polishing and other processes producing line factory).

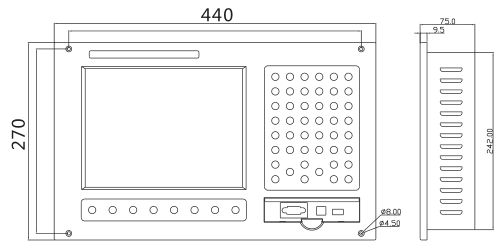

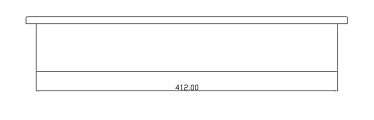

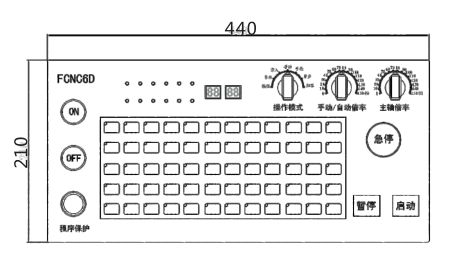

Size: