SMC-NCT-03 Three Axis Punching CNC Controller

Feature:

1. Add T axis die change control;

2. Max support 36 working position, can customize mould library;

3. Easy to learn, friendly interface, convenient operation;

4. Can preview process track and real-time following;

5. Support twice relocation and clamp avoid function, realize palte no dead zone process;

6. With single punch, continuous punch, step punch etc. different kinds of punching mode, increase the process efficency;

7. Can recognize CAD convert code, compatible with usual punching machine software code, support CAM template programming;

8. With complete self-diagnostic function, internal and external real-time display, it will show alarm if any exception.

Optional Spare Parts:

(Handheld box-CNC4A)

(Handheld box-CNC4A)  (Additional panel- FCNC4M)

(Additional panel- FCNC4M)

Function:

1. X, Y, T three axis micron level interpolation accuracy controlling;

2. USB/U dis/RS232COM etc many kinds of communication mode, to help users achieve different data transmission and software upgrades easily.

3. CAD graphics automatic conversion processing program, CAM graphics library function, include a variety of commonly used graphics.

4. Breakpoint memory function, can choose from the breakpoint to continue processing under program abnormal circumstances .

5. Single-punch, continuous,single-stage of a variety of processing methods, oplate automatic relocation, clamp protection zone function.

6. With input/output module, available to extend I/O count.

7. The highest fast moving speed reach 60 M/min, the highing feed speed reach 30M/min.

8. Servo AB encoder closed-loop control to ensure feeding accuracy.

9. Outage saving function, password protection function, screen protection function, etc.

10. Die T axis offset compensation function

11. Fully compatible with procam CAM software and addition punching machine special compound instruction.

12. CAM wizard type punching instruction programming, can directly start punching processing program after filling in hole location information.

13. DXF + G code templates graphics analysis, can convert CAD files to processing files directly, no need softdog supporting.

14. Available to preview processing code graphics, real-time tracking processing locus during processing.

15. Support powerful class B macro analysis function, convenient for users to develop their own motion control program.

16. Dead point detection, clamps loosen alarmimg, main motor doesn’t open alarming etc richful protection functions.

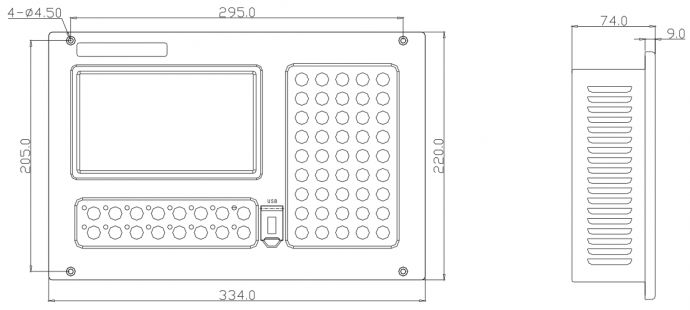

Size: