SMC-NCT-04 Four Axis Punching CNC Controller

Feature:

1. Add T axis die change control and C axis die rotary control;

2. Max support 36 working position, can customize mould library;

3. Easy to learn, friendly interface, convenient operation;

4. Can preview process track and real-time following;

5. Support twice relocation and clamp avoid function, realize palte no dead zone process;

6. With single punch, continuous punch, step punch etc. different kinds of punching mode, increase the process efficency;

7. Can recognize CAD convert code, compatible with usual punching machine software code, support CAM template programming;

8. With complete self-diagnostic function, internal and external real-time display, it will show alarm if any exception.

Optional Spare Parts:

(Handheld box-CNC4A)

(Handheld box-CNC4A)  (Additional panel- FCNC4M)

(Additional panel- FCNC4M)

Function:

1. Control axis number X, Y, T, C four axis micron level interpolation accuracy;

2. USB, U disk, RS232COM communications and other communication methods, easy to help users to achieve different data

transmission requirements and software upgrades;

3. Perfect self diagnosis function, internal and external status real-time display, abnormal immediately alarm;

4. CAD graphics automatic conversion processing procedures, CAM graphics library functions, there are a variety of commonly used graphics;

5. According to the program code automatically generated processing track, machining process to track the actual location;

6. Breakpoint memory function, program exceptions can be selected from the breakpoint to continue processing;

7. Two hand punching machine die change system, when the program is for instructions and prompts the system to suspend

mode need to replace the mold;

8. Mold rotating function, you can press the complex shape, automatic angle optimization;

9. With input / output module, I/O points can be extended;

10. Maximum fast moving speed up to 60 m / min, the maximum feed rate of up to 30 m / min;

11. Power save function, password protected screen saver function etc;

12. Support two relocation function and clamp avoidance function, realize the plate without dead time processing;

13. Fully compatible with CAM and other PROCAM software, and additional punch special composite directive;

14. CAM wizard punching instruction programming, can be directly used to fill in the hole information directly to start processing for punching;

15. DXF+G code template graphics resolution, can be directly converted to CAD files for processing files, without the need to encrypt the dog support;

16. Support the powerful B macro analysis function, to facilitate users to develop their own motion control program.

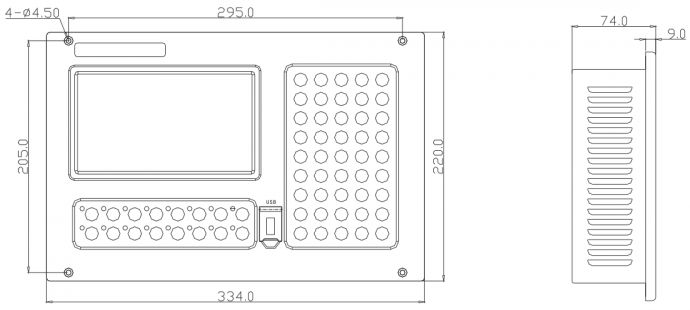

Size: